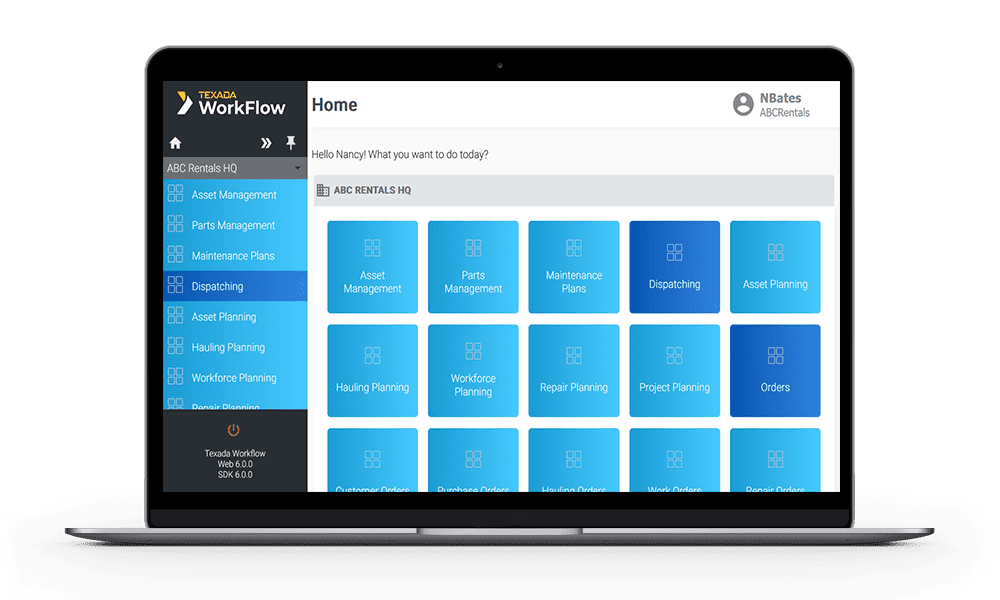

TEXADA WORKFLOW

Boost your business operations with pre-built and custom rental equipment workflow applications.

WORKFLOW FEATURES

Discover the advantages of Texada WorkFlow for your rental equipment business today and experience the versatility of Texada solutions.

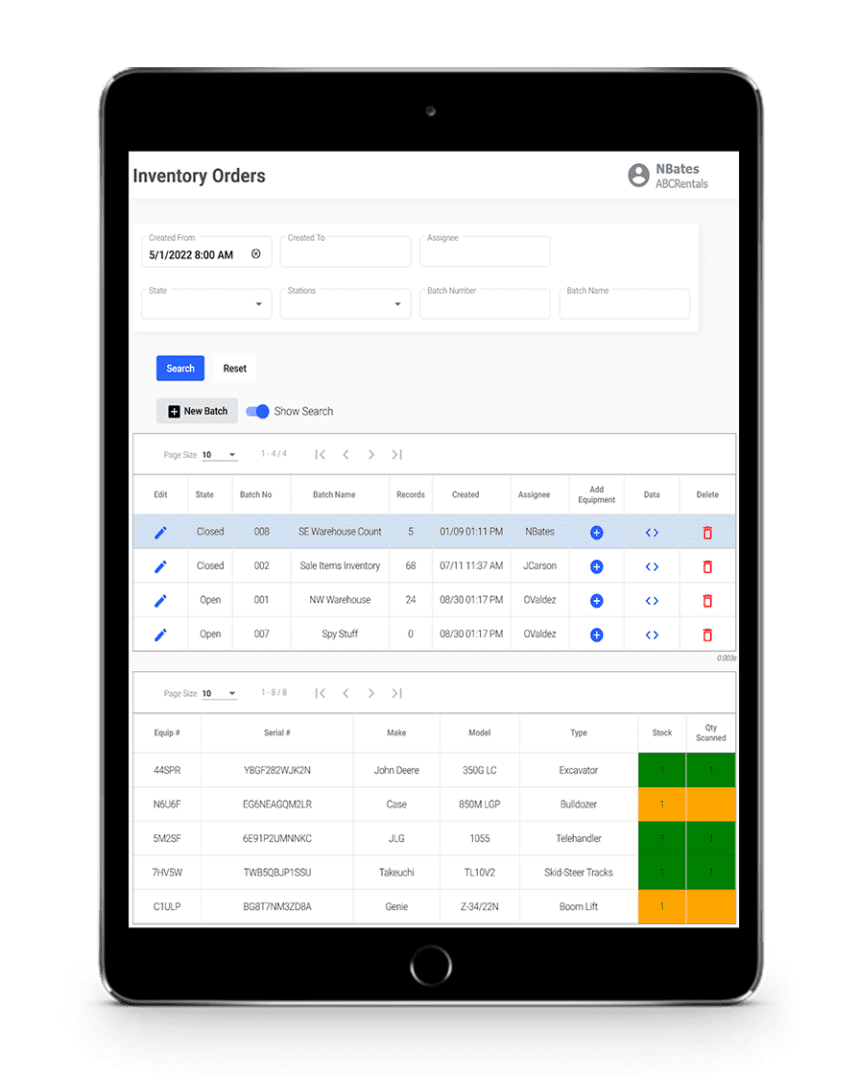

TURNKEY APPLICATIONS

Tackle your most difficult equipment rental challenges with the ultimate workflow toolkit.

Current applications include:

Enhance the business functions that your team needs today with Texada WorkFlow.

CUSTOMIZABLE OPTIONS

Streamline rental management processes with rental equipment workflow and asset tracking software. Use an agile, customizable tool to create solutions that empower your team and build exceptional customer experiences.